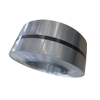

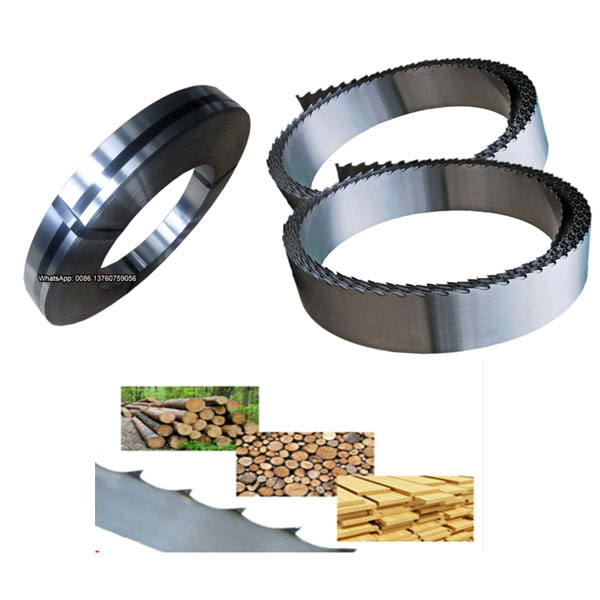

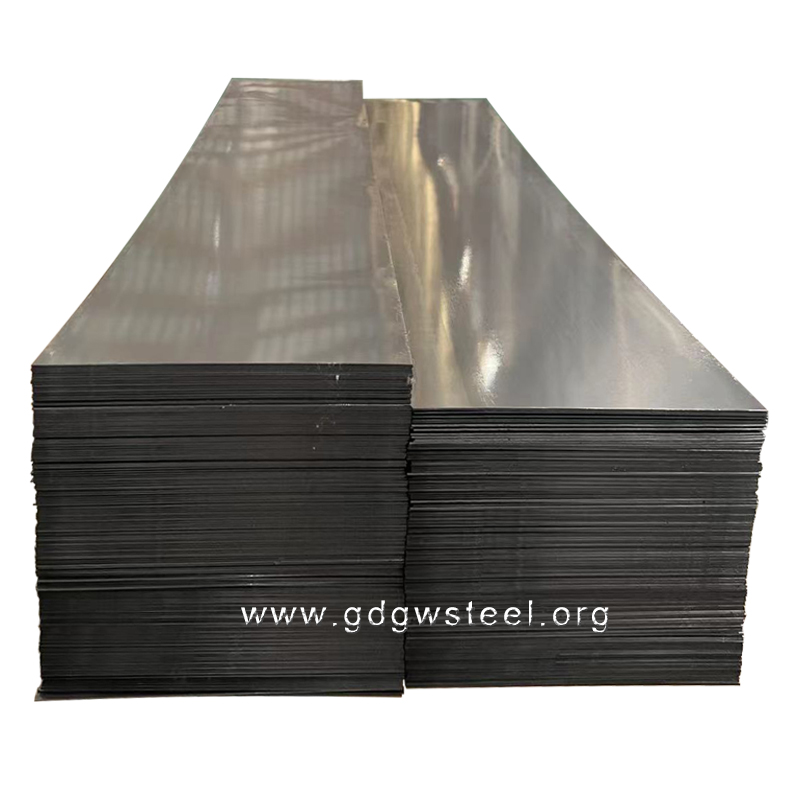

Steel material SK5 carbon steel for band saw blade

Guangzhou Cgoodsteel Co.,Ltd band saw blade steel material SK5,C75,SAE1075, C75Cr1 with durable properties, are optimized for wide application, such as wood cutting, frozen meat, paper, leather, timber, sponge, rubber, stone etc.

Learn More