| Product Name |

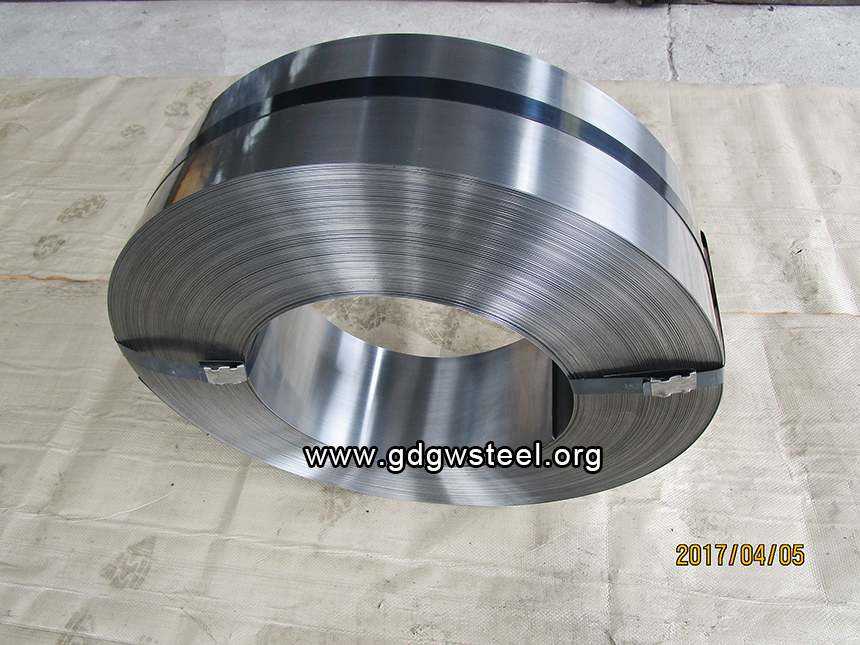

hardened and tempered steel strips/coils/sheet cold rolled annealed steel strips/coils/sheet spring steel strip high carbon steel strip |

| Standard | EN, DIN, JIS, AISI, ASTM |

| Type | Coil/Sheet/Plate/Strip |

| Material Grade |

C50S, C55S, C60S, C67S, C70S, C75S, C80S, C95S, 50CrV4, 51CrV4, 75Cr1, SK5, 60Si2Mn, SK5 (SK85), 65G sae1045, sae1050, sae1060, sae1065, sae1070, sae1075, sae1095 C100S CK45, CK50, CK55, CK60, CK67, CK70, CK75, 65Mn, 50#, 60#, T8, T10, DA6 Stainless steel: AISI 420, 430, Bimetal steel strip: M42 & D6A / x32 |

| Conditions | hardened & tempered, annealed, cold rolled |

| Thickness | 0.10mm to 5.00mm |

| Width | 3mm to 1200mm |

| Surface color | nature, blue, white, black, yellow, bright, polished |

| Hardness |

below 19HRC for annealed process, 29-55HRC for hardened& tempered process, 21-28HRC for cold rolled process |

| Edge | slit/sheared edge, round edge, square edge |

| Application |

rolling shutter door spring, band saw blades, steel springs, coil springs, masonary tools, construction tool, agricultural tools, auto parts, springs, metal parts, washers, spacers, clips, pin, inserts, and others, etc. |

| Coil Weight | 30kgs - 2500kgs |

| Coil ID | 300-500MM or as per request |