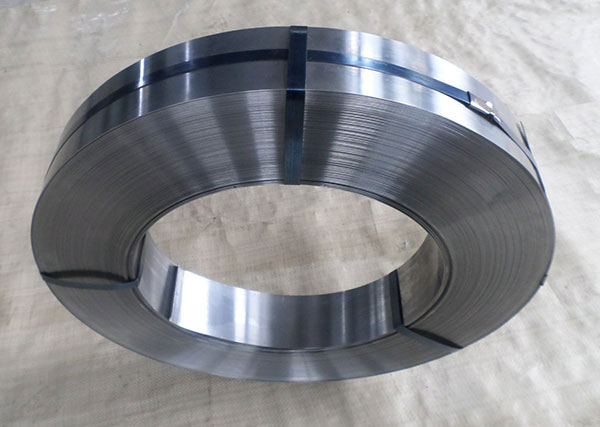

SK5 high carbon steel

After quenching and tempering, sk5 steel has high hardness and wear resistance. SK5 high carbon steel is used to make various tools which request high hardness and wear resistance, such as the shape of the mold and the simple punch, metal cutting tools, drilling tools, woodworking cutter, countersink drills, axes, chisels, hand saws longitudinal and fitter assembly tools, rivet die and other minor tools. We can supply SK5 steel in hardened & tempered process and annealing process.

|

Delivery condition (strip,coil,sheet)

|

Grade based on DIN Standard

|

Hardened and tempered conditions

|

|

|

Hardness 29-55HRC

|

|||

|

thickness

|

Width

|

||

|

High carbon steel

|

CK50,CK55, CK60,CK67,

CK70,CK75,C75Cr1, SK5

|

0.15-2.5mm

|

8-300mm

|

|

Alloy spring steel

|

50CrV4, 51CrV4, 60Si2Mn

|

0.20-2.2mm

|

8-180mm

|

|

Stainless spring steel

|

3Cr13-6Cr13

|

0.20-2.5mm

|

8-150mm

|

|

Edge process

|

slit edge; both rounded; one side round, one side slit; square etc

|

||

|

Finish surface

|

polished (blue, yellow, white, grey-blue, black, bright) or Nature etc

|

||

|

Tolerance

|

thickness +/-0.03mm max; width +/-0.3mm max

|

||

|

Physical Property

|

tensile strength - 1200-1850N/mm2

|

||