SAE 1075 CK75 C75 C75s Spring Steel Strips

|

Material grade Chemical Composition |

Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickle (Ni) |

|

SAE1075 CK75 C75 C75S

|

0.70-0.80 | 0.15-0.35 | 0.60-0.90 | max 0.035 | max 0.035 | max 0.40 | max 0.40 |

Guang Zhou Cgood steel produces cold rolled spring steel strips supplied below,

| Product Name |

hardened and tempered steel strips / coils / sheet / plate cold rolled annealed steel strips / coils / sheet / plate spring steel strips / coils / sheet / plate high carbon steel strips / coils / sheet / plate

|

| Standard |

EN, DIN, JIS, AISI, ASTM

|

| Type |

coils / sheet / plate / strips

|

| Material grade |

SAE 1045 C45 CK45 C45S SAE 1050 C50 CK50 C50S SAE1060 C60 CK60 C60S SAE 1065 SAE 1070 C67S CK67 C67S SAE 1075 1074 C75 CK75 C75S SAE 1080 C80S C100S 1095 C95 CK95 C95S 50CrV4 51CrV4 75Cr1 75NI8 SK5 60Si2Mn SK85 SK51 65G 65Mn 50# 60# T8A T10 Stainless steel strip: AISI 420 430 201 301 Bimetal steel strip: M42 M51 / D6A X32

|

| Conditions |

Hardened and tempered, annealed, cold rolled

|

| Thickness |

0.10mm to 5.0mm for hardened and tempered conditions 0.10mm to 6.00mm for annealed conditons

|

| Width |

2mm to 500mm for hardened and tempered conditions 2mm to 1250mm for annealed conditions

|

| Surface color |

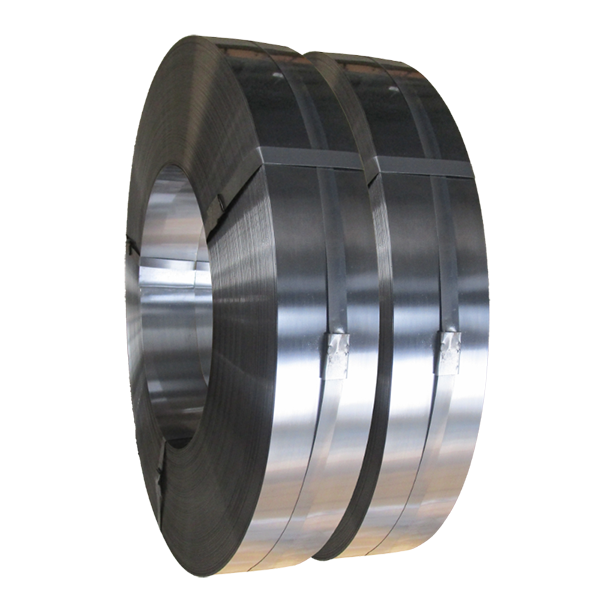

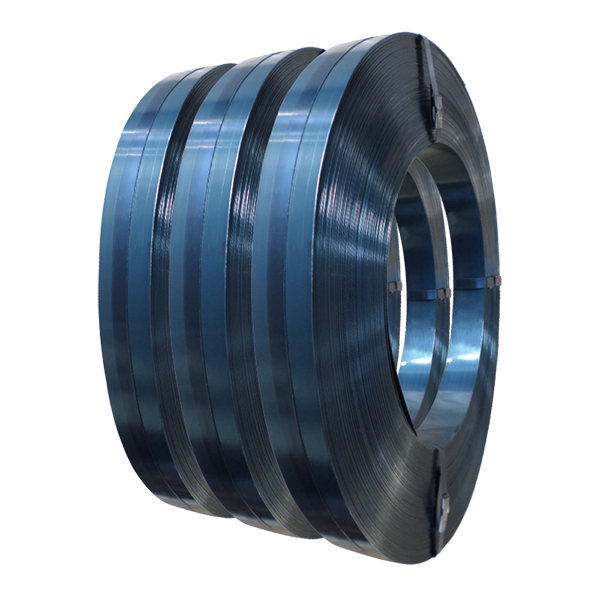

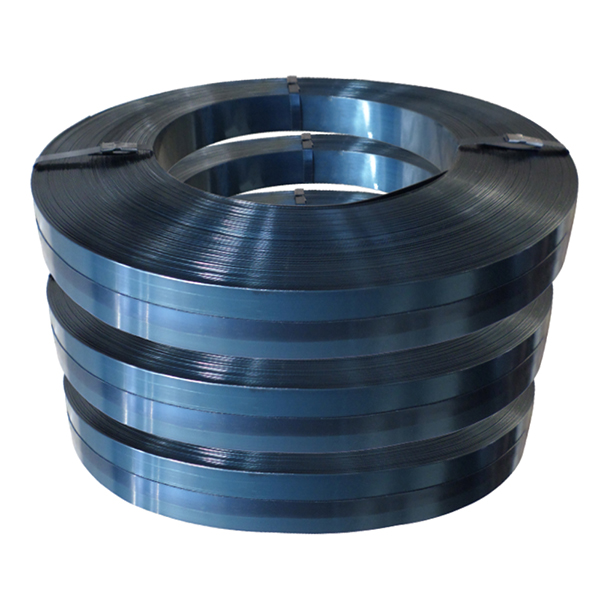

nature, blue, yellow, white, black, bright, polished

|

| Hardness |

below 19HRC max 180 HV for annealed process 29-55 HRC for hardened and tempered process 21-28 HRC for cold rolled process

|

| Edge |

slit / sheared edge, round edge, square edge

|

| Application |

rolling shutter door spring, band saw blades, steel spring, coils springs, auto parts etc,

|

Spring steel strips are widely used in various application.

Guang Zhou Cgood steel Co., Ltd, has very strict high quality control on the heat treatment spring steel strips every step in the production line.

- Uniform Hardness and Strict size tolerance and width tolerance:

We have advanced facility to control the hardness and sizes tolerance within customers request and series of equipment to test material machnical properties strictly and make record to the test result.

- Flatness and straightness Control

We performa every step necessary to make sheets virtually flat. We have numerous in-house levelling systems, each one designed to flatten metal within its own optimum thickness range.

- Safety package & delivery on-time

Each coil is oiled and wrapped in plastic film and then wrapped with anti-rust paper and put into 20ft container. All orders are scheduled to finish and delivery on-time.

All specific technical data, please click the website page: Technical Data

Any inquiry, please contact us: sophieliang@gdgwsteel.com , phone or WhatsApp No: 0086 13760759056