Heat treatment 51CrV4 spring steel strip

Guangzhou Cgood Steel Co., Ltd is a professional manufacturer, supplying high quality heat treatment 51CrV4 spring steel strip. 51CrV4 spring steel has good mechanical properties with high hardenability. Adding vanadium (V) refines the grain of steel, it reduces overheat sensitivity and improves strength and toughness. 51CrV4 steel heat treatment has high fatigue strength and a high yield ratio.

Generally speaking, the chemical composition of 51CrV4 steel should meet the following requirements:

51CrV4 steel composition

Carbon: 0.47%-0.55%,

Silicon: max 0.40%,

Manganese: 0.70-1.10%

Phosphorus: max 0.035%

Sulfur: max 0.0035%

Chromium: 0.90%-1.20%

Nickel: max 0.25%.

51CrV4 carbon steel properties: strength, elasticity, fatigue resistance, hardenability.

Factory production 51CrV4 Specification range

Cold rolled condtions: 21-28HRC

Annealed conditions: below 19HRC

Hardened and tempered condtions: 29-59HRC

Thickness: 0.15mm to 5.50mm

Width: 2mm to 600mm

Edge: slit, round, square edge

Surface: nature, bright, polished, white, blue, ect

51CrV4 spring steel strip application

51CrV4 spring steel strip is used for producing band saw blade, automotive industry (spring components for suspension systems, shock absorbers, brake systems, etc.), mechanical engineering (various springs, tension springs, torsion springs, etc.), environmental control systems (spring components in air conditioning, refrigeration and heating systems), construction industry (springs for construction equipment such as doors, windows, rolling doors and elevators)

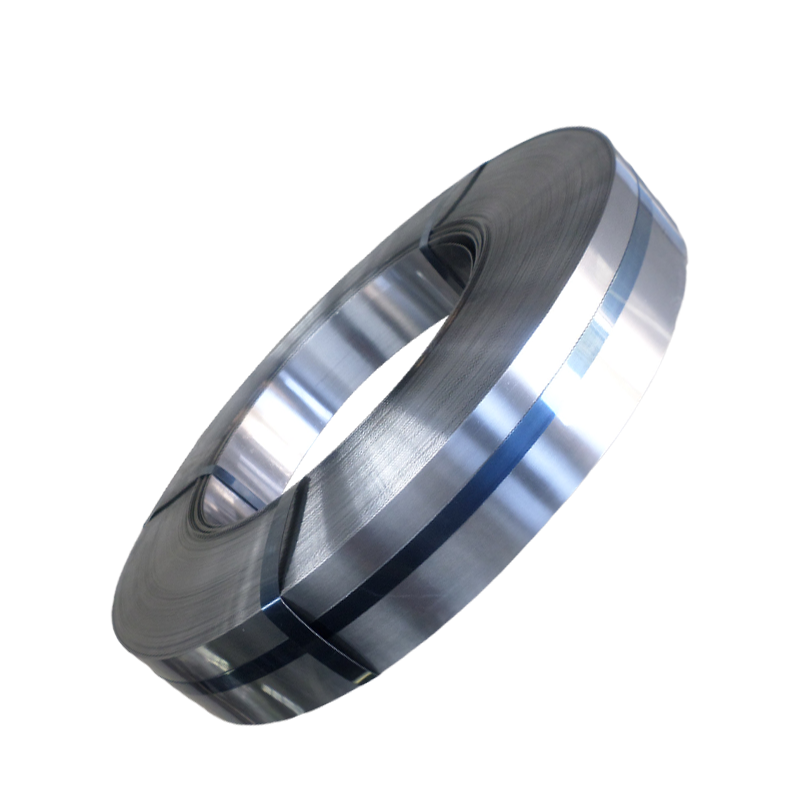

Factory product photo 51CrV4 steel strip