C75S / CK75 Spring Steel Strip | High Carbon Steel | Hardened & Tempered | CGOOD STEEL

C75S (also known as CK75) is a premium hardened and tempered high carbon steel strip, specifically engineered for demanding spring applications. At GDGW Steel, we supply C75S/CK75 spring steel strip that offers an exceptional combination of high tensile strength, excellent fatigue resistance, and remarkable durability. Our steel undergoes a precise hardening and tempering process, ensuring consistent performance and reliability for your most critical components. If you are searching for a robust C75S high carbon steel strip or its equivalent CK75 spring steel, our product is the ideal choice for manufacturing springs, blades, scrapers, and various high-stress parts.

Guang Zhou Cgood steel Co., Ltd, produces C75S CK75 hardened and tempered high carbon steel strip supplied below,

|

Material grade

Chemical Composition |

Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickle (Ni) |

|

C75S, CK75

|

0.70-0.80 | 0.15-0.35 | 0.60-0.90 | max 0.035 | max 0.035 | max 0.40 | max 0.40 |

Factory production C75S CK75 Specification range

| Material Grade | C75 CK75 |

| Cold rolled condtions: | 21-28HRC |

| Annealed conditions | below 19HRC |

| Hardened and tempered condtions | 29-59HRC |

| Thickness: | 0.15mm to 5.50mm |

| Width | 2mm to 600mm |

| Edge Treatment | slit, round, square edge |

| Surface Treatment | nature, bright, polished, white, blue, ect |

| Standard | DIN 17222 |

| Equivalent material | SAE 1075 |

Mechanical properties:

- cold-rolled and soft-annealed state, the tensile strength does not exceed 640 MPa, the elongation is at least 12%, and the Brinell hardness does not exceed 190

- cold-rolled, quenched and tempered state, the tensile strength is between 1320 and 1870 MPa, and the hardness is between 390 and 555

Heat treatment:

C75S CK75 can be processed by a variety of heat treatment methods, including annealing, normalizing and hardening & tempering.

- Annealing temperature is between 650 and 690°C;

- Oil quenching temperature is between 810 and 840°C, and tempering temperature is between 300 and 500°C.

Key Features & Benefits of Our C75S/CK75 Steel Strip

- High Carbon Content: Ensures superior strength and wear resistance, making it perfect for high carbon steel spring applications.

- Hardened & Tempered: The controlled thermal treatment process guarantees optimal hardness, toughness, and elasticity, preventing premature failure.

- Excellent Spring Properties: Provides outstanding yield strength and fatigue life, essential for reliable C75S spring steel strip performance.

- Consistent Quality: Our strict quality control ensures uniform mechanical properties and dimensional accuracy across every batch of CK75 steel strip.

- Wide Applications: Ideal for flat springs, saw blades, measuring tapes, and other precision parts that require a durable and resilient material.

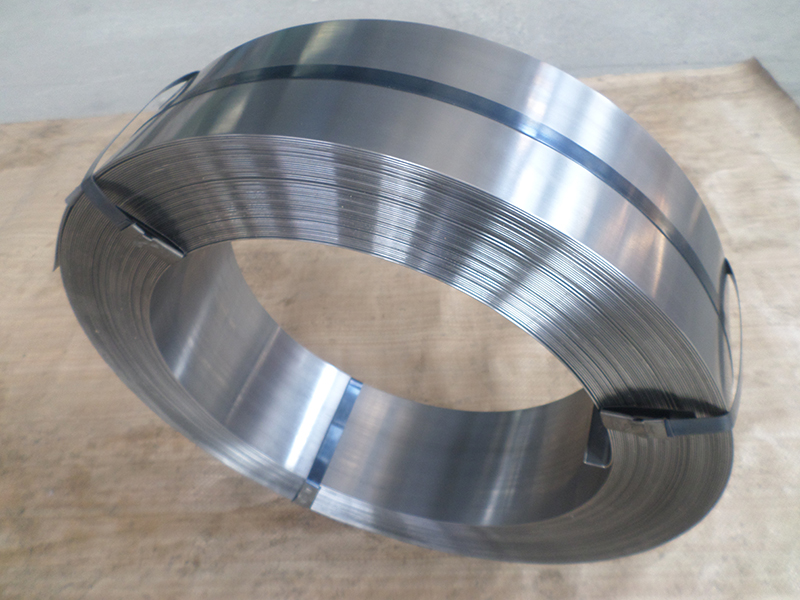

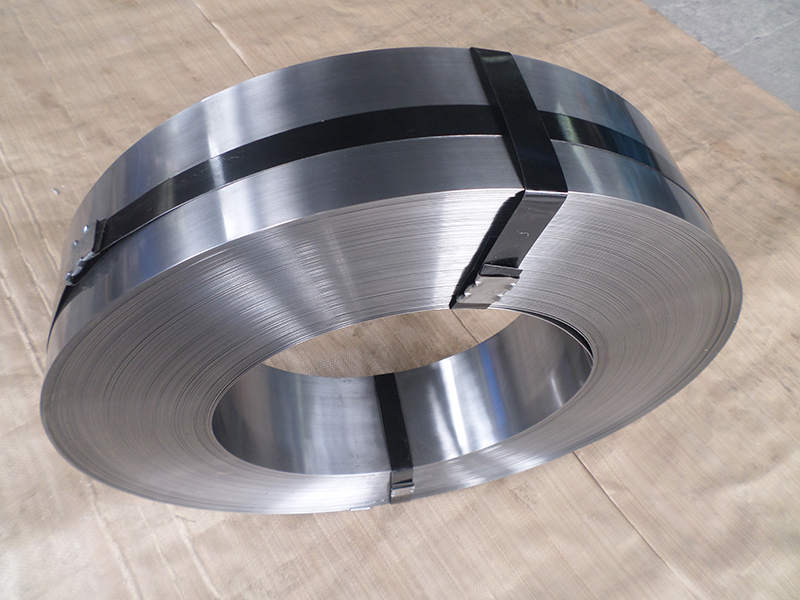

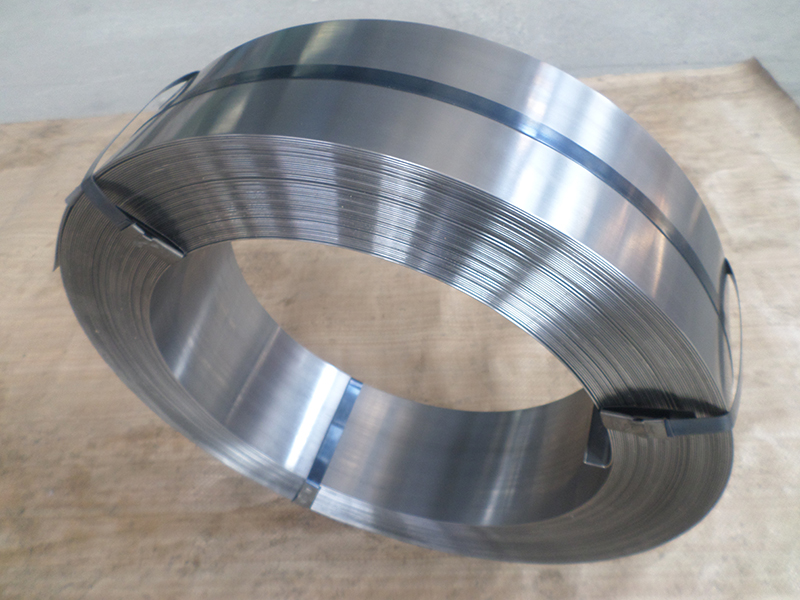

Factory Photo

Application:

C75S CK75 steels are mainly used to manufacture various springs, including coil spring, spring clips, lock hook, clock hands, band saw blade, trowels etc.

Quality Control

Guang Zhou Cgood steel Co., Ltd, has very strict high quality control on the hardened and tempered high carbon steel strip and cold rolled annealed high carbon steel strip in the production line.

Uniform Hardness and Strict size tolerance and width tolerance:

We have advanced facility to control the hardness and sizes tolerance within customers request and series of equipment to test material machnical properties strictly and make record to the test result.

Flatness and straightness Control

We performa every step necessary to make sheets virtually flat. We have numerous in-house levelling systems, each one designed to flatten metal within its own optimum thickness range.

Safety package & delivery on-time

Each coil is oiled and wrapped in plastic film and then wrapped with anti-rust paper and put into 20ft container. All orders are scheduled to finish and delivery on-time.