C67S CK67 hardened and tempered carbon steel strip

Guangzhou Cgood Steel Co., Ltd is a leading manufacturer in China, producing and exporting large quanties of C67S CK67 hardened and tempered carbon steel strip with the following characteristics,

Chemical composition:

Carbon (C): 0.65 - 0.73%

Silicon (Si): 0.15 - 0.35%

Manganese (Mn): 0.6 - 0.9%

Phosphorus (P): ≤0.025%

Sulfur (S): ≤0.025%

Chromium (Cr): ≤0.4%

Nickel (Ni): ≤0.4%

Molybdenum (Mo): ≤0.1%

Mechanical properties:

1- Tensile strength (σb): ≤600 MPa (annealed or annealed flat state), ≤1140 MPa (cold rolled state), 1200~1900 MPa (quenched and tempered state)

2- Yield point (σs): ≤510 MPa (annealed or annealed flat state)

3- Elongation or elongation after fracture (δ): ≥16% (annealed or annealed flat state)

4- Hardness: HV ≤200 (annealed or annealed flat state), HV ≤315 (cold rolled state), HV 370~580 (quenched and tempered state)

Factory production C67S CK67 Specification range

Cold rolled condtions: 21-28HRC

Annealed conditions: below 19HRC

Hardened and tempered condtions: 29-59HRC

Thickness: 0.15mm to 5.50mm

Width: 2mm to 600mm

Edge: slit, round, square edge

Surface: nature, bright, polished, white, blue, ect

Application areas:

C67S CK67 steels are widely used in the manufacture of various spring products due to its excellent elasticity and toughness, such as automobile shock absorber springs, engine valve springs, piston rods and cylinder sleeves in hydraulic parts, etc. In addition, it is also used to manufacture important spring components in precision instruments and equipment, such as clocks, instruments and optical instruments, etc.

Heat treatment:

C67S CK67 steels can be heat treated or cold drawn to obtain higher strength, hardness, elasticity, and appropriate toughness and plasticity. Under the same surface condition and complete hardening, its fatigue limit is no worse than that of alloy spring steel.

Corresponding standards and grades:

The European standard steel grade corresponding to C67S CK67 steels are 1.1231, which complies with the EN 10132-4-2002 standard and is classified as spring steel.

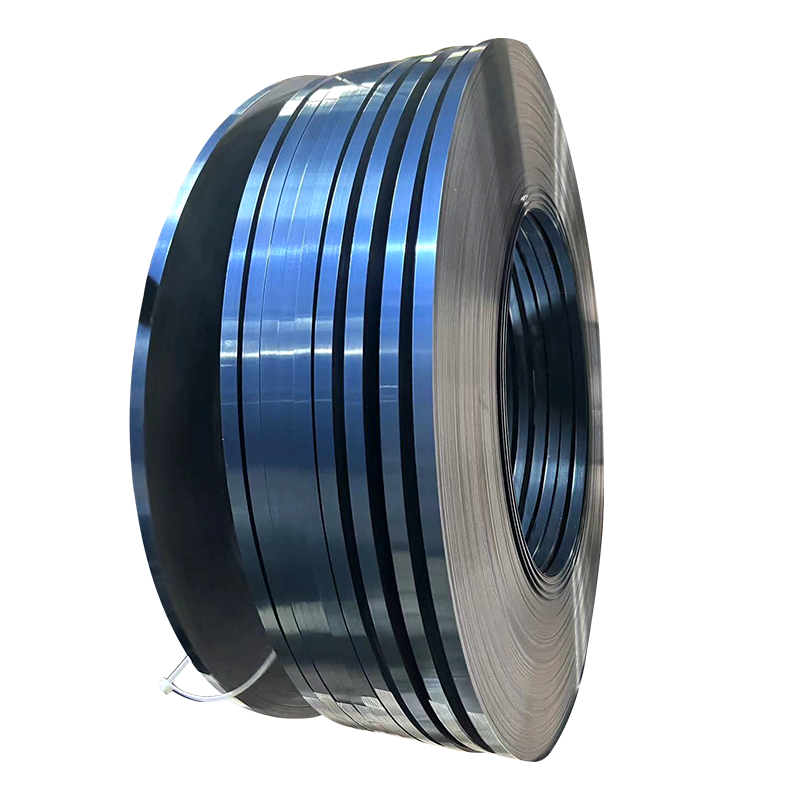

Factory product photo: