Bimetal strip X32 CrMoV4 cold rolled steel strip for band saws

Guangzhou Cgood Steel Co., Ltd is a professional manufacturer, supplying saw blade steel strip material X32 CrMoV4 with hard wearing properties. X32 CrMoV4 bimetallic cold rolled steel strips have strict requirements on dimensional accuracy during the manufacturing process, including width tolerance, thickness tolerance, parallelism, straightness deviation, flatness deviation and twisting. This material provide strength, durability, cutting performance, long service life, cost effective, safety.

Generally speaking, the chemical composition of X32 CrMoV4 steel should meet the following requirements:

X32 CrMoV4 steel composition

Carbon: 0.30%-0.35%,

Silicon: 0.17%-0.35%,

Manganese: 0.90-1.10%

Phosphorus: max 0.010%

Sulfur: max 0.010%

Chromium: 3.80%-4.10%

Molybdenum: 1.20%-1.40%,

Nickel: 0.70%-0.85%.

The microstructure of X32 CrMoV4 steel is mainly composed of martensite, bainite and residual austenite. Among them, martensite is a kind of organization with high hardness and brittleness, while bainite has high toughness and plasticity. Therefore, during the heat treatment process, it is necessary to control the organization structure through reasonable process parameters to achieve the ideal performance requirements.

Performance requirements of X32 CrMoV4 steel

1. High strength: X32 CrMoV4 steel has high yield strength and tensile strength, and can withstand large loads and impact forces.

2. High toughness: X32 CrMoV4 steel has high toughness and plasticity, and is not easy to break when subjected to impact or vibration.

3. High wear resistance: X32 CrMoV4 steel has high surface hardness and can resist wear and corrosion.

Heat treatment process of X32 CrMoV4 steel

The treatment process of X32 CrMoV4 steel mainly includes annealing, cold rolling, quenching and tempering. These steps can eliminate the internal stress of steel parts, refine grains, improve organization, and improve the plasticity and toughness of steel.

Factory production X32 CrMoV4 Specification range

Cold rolled condtions: 21-28HRC

Annealed conditions: below 19HRC

Hardened and tempered condtions: 29-59HRC

Thickness: 0.15mm to 5.50mm

Width: 2mm to 600mm

Edge: slit, round, square edge

Surface: nature, bright, polished, white, blue, ect

We can supply back material X32 CrMoV4, D6A steel strip and also Bimetal steel strip (carbon steel X32 CrMoV4, D6A topped with HSS M42/M51)

HSS M42/D6A Bimetal steel strip

HSS M42/X32 CrMoV4 Bimetal steel strip

HSS M51/X32 CrMoV4 Bimetal steel strip

HSS M51/D6A Bimetal steel strip

Bimetal strip for: producing bimetal saw blade, hacksaw blade,

power hacksaw blade, band saw blade, jig saw blade

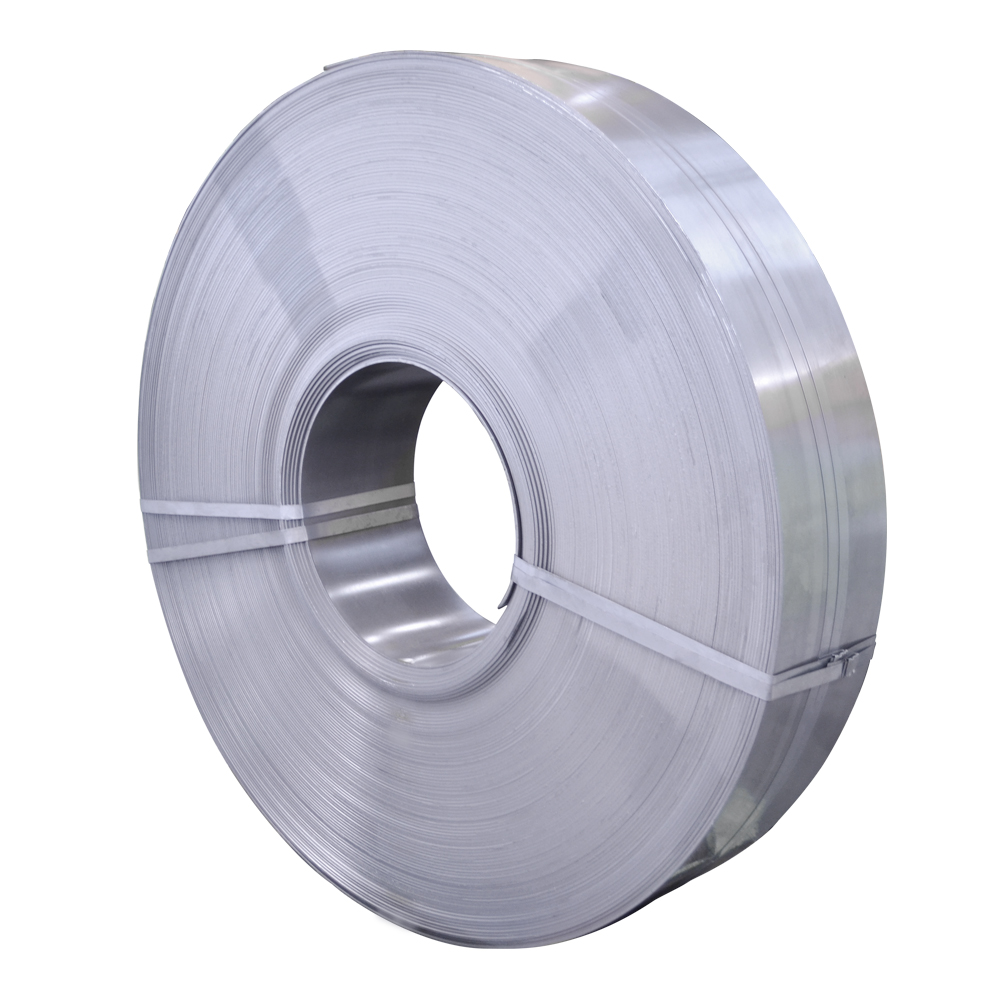

Shape: steel coil

Technology: laser welding HSS Bimetal steel strip

Common size: 0.65x 13mm, 0.9 x 19mm, 0.9 x 27mm, 1.1 x 34mm, 1.3 x 41mm, 1.6 x 54mm,size can

Factory X32 CrMoV4 steel for band saws