60SiCr7 SUP7 60Si2MnA high carbon manganese spring steel strip

Guangzhou Cgood Steel Co., Ltd is a professional manufacturer, producing 60SiCr7, SUP7, 60Si2MnA spring steel strip with heat treatment. 60SiCr7, SUP7, 60Si2MnA are spring alloy steel element with high hardenability, high toughness and plasticity, low decarburization, good tempering stability, good working performance and low cost. It is suitable to make leaf springs for heavy, medium and small automobiles and other medium-section leaf springs and spiral springs.

Generally speaking, the chemical composition of 60SiCr7, SUP7 and 60Si2MnA spring steel should meet the following requirements:

60SiCr7, SUP7 and 60Si2MnA steel composition

Carbon: 0.54%-0.60%,

Silicon: 1.5%-2.0%,

Manganese: 0.70-1.00%

Phosphorus: max 0.035%

Sulfur: max 0.035%

Chromium: max 0.35%

60SiCr7, SUP7 and 60Si2MnA are equivalent materials.

60SiCr7 as DIN standard,

SUP7 as Japanese standard

60Si2MnA as GB standard

Heat treatment process of 60SiCr7, SUP7, 60Si2MnA steel

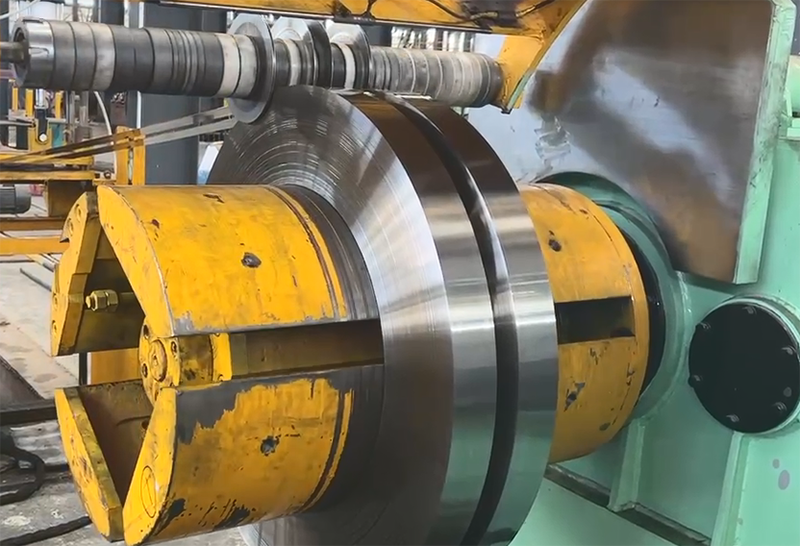

The treatment process of these 3 steel grade materials mainly includes annealing, cold rolling, quenching and tempering.

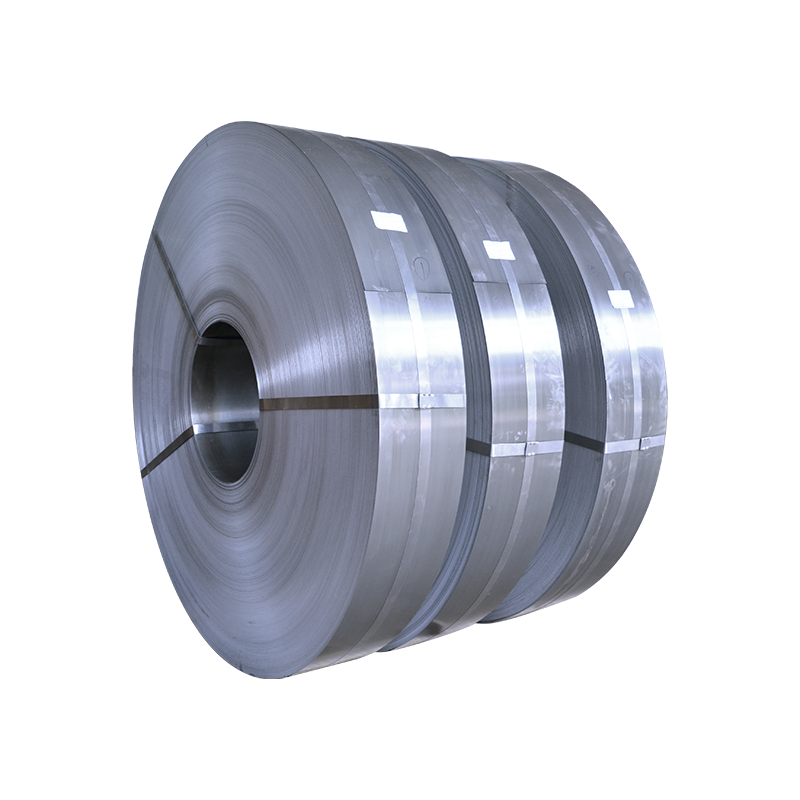

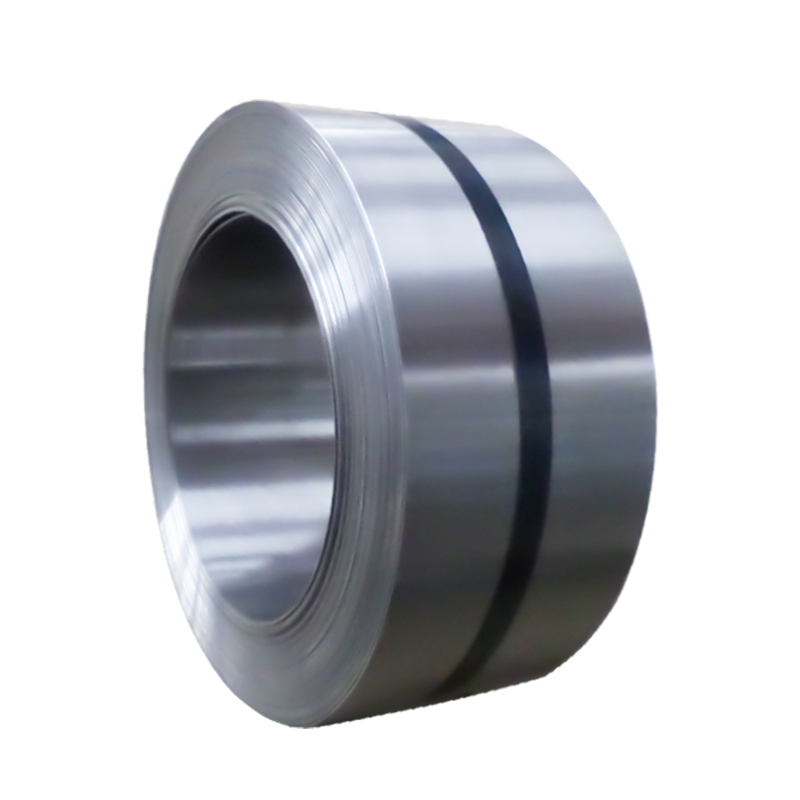

Factory production 60SiCr7, SUP7, 60Si2MnA Specification range

Cold rolled condtions: 21-28HRC

Annealed conditions: below 19HRC

Hardened and tempered condtions: 29-59HRC

Thickness: 0.15mm to 5.50mm

Width: 2mm to 600mm

Edge: slit, round, square edge

Surface: nature, bright, polished, white, blue, ect

Factory product photo