Factory steel strips production capacity below:

Hardened & Tempered Steel Strips

Hardening and Tempering is a thermal process that strengthens cold rolled steel strips through a controlled heating and cooling process. This process of hardening and tempering improves the mechanical properties, flatness of the steel strip and gives a tougher and more durable product

Cold Rolled and Spheriodized Annealed Steel Strips

Annealed steel strips/ coils are produced by the process of annealing wherein to alter its physical and properties such as strength andhardness. Annealing increases the ductility and makes steel softer

Company Product Specification We Supply

| Product Name |

hardened and tempered steel strips/coils/sheet cold rolled annealed steel strips/coils/sheet spring steel strip high carbon steel strip |

| Standard |

EN, DIN, JIS, AISI, ASTM

|

| Type |

Coil/Sheet/Plate/Strip

|

| Material Grade |

C50S, C55S, C60S, C67S, C70S, C75S, C80S, C95S, 50CrV4, 51CrV4, 75Cr1, 80CrV2, SK5, 60Si2Mn, SK5 (SK85), SK51, 65G sae1045, sae1050, sae1060, sae1065, sae1070, sae1075, sae1095 C100S CK45, CK50, CK55, CK60, CK67, CK70, CK75, 65Mn, 50#, 60#, T8, T10, DA6 Stainless steel: AISI 420, 430, Bimetal steel strip: M42 & D6A / x32

|

| Conditions |

hardened & tempered, annealed, cold rolled

|

| Thickness |

0.10mm to 5.00mm

|

| Width |

3mm to 1250mm

|

| Surface color |

nature, blue, white, black, yellow, bright, polished

|

| Hardness |

below 19HRC for annealed process, 29-55HRC for hardened& tempered process, 21-28HRC for cold rolled process

|

| Edge |

slit/sheared edge, round edge, square edge

|

| Application |

rolling shutter door spring, band saw blades, steel springs, coil springs, masonary tools, construction tool, agricultural tools, auto parts, springs, metal parts, washers, spacers, clips, pin, inserts, and others, etc.

|

| Coil Weight & Coil ID |

30kgs - 2500kgs coil weight, 300-500mm coil ID or as per request

|

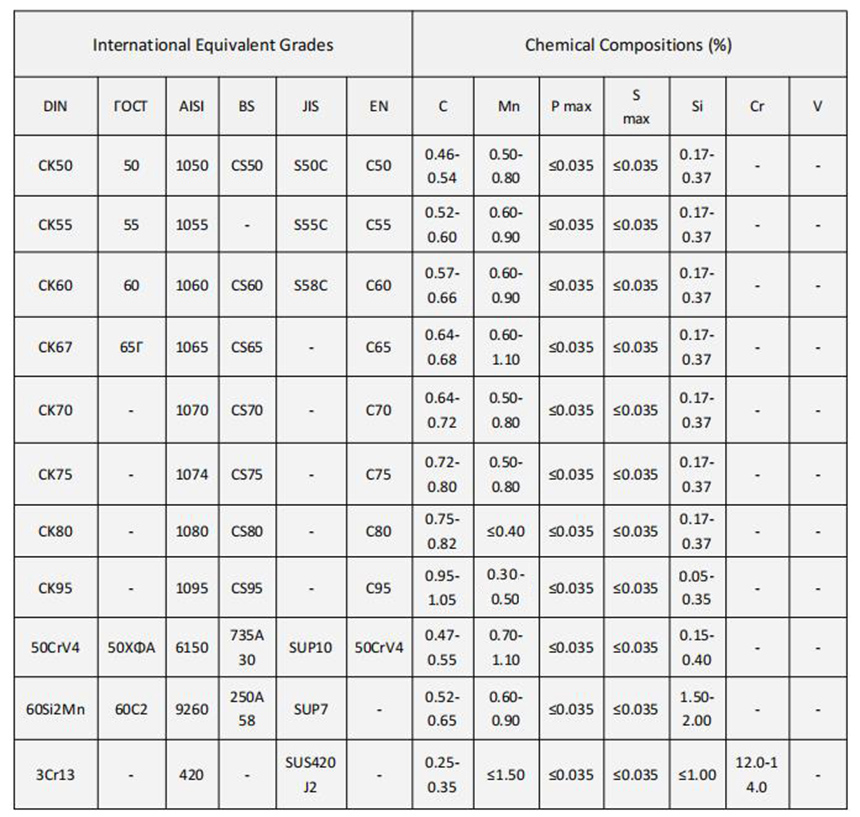

Material Grades